Additive

Additive Manufacturing: Innovation and Precision with WAAM (Wire Arc Additive Manufacturing) Technology

Our Technology

At ETEO, we are excited to use Wire Arc Additive Manufacturing (WAAM) technology, which is part of the Direct Energy Deposition (DED) category of 3D printing technologies. This revolutionary technology allows us to work on large parts, optimizing the process and reducing deposition time. The result? Components with high strength and flexibility that conventional methods cannot match.

Our machines

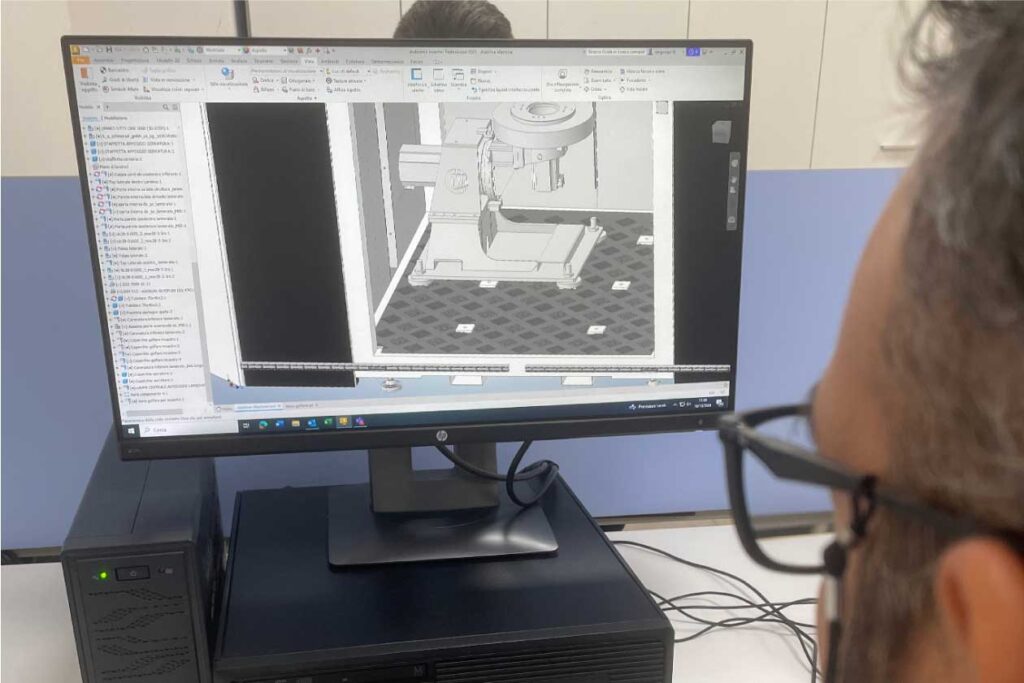

To meet various needs, we have developed the E-300 and E-500 models. These machines offer extraordinary flexibility, allowing for 3 or 5-axis configurations. Our machines ,upon request, can be equipped with a thermal imaging camera for temperature feedback control, ensuring constant and precise monitoring throughout the production process.

Advanced Software

Technology alone is not enough: therefore, we use CAD software for modeling and design, and CAM software to develop efficient printing strategies. With temperature feedback control, we can keep adduction parameters under control, thus ensuring superior quality of the final product.

Prototyping and Customer Collaboration

At ETEO, we believe in active collaboration with our customers. From the earliest stages of the project, we share with them the design, deposition strategy and quality verification of the manufactured product. This approach allows us to ensure that the end result fully meets their expectations.

Materials Used

We offer a wide range of materials for additive manufacturing, including structural steel, stainless steel, nickel-based alloys, and high-strength aluminum. These materials are selected for their excellent mechanical properties and corrosion resistance, making them ideal for multiple industrial applications.

Industrial Applications

Our WAAM (Wire Arc Additive Manufacturing) technology is incredibly versatile and has applications in a variety of industries:

Automotive

Rapid production and the versatility of available materials enable optimized lead times and improved efficiency in the production of complex, customized components.

Energy

WAAM (Wire Arc Additive Manufacturing) can be used in the energy sector for large-scale component production.

Defense

The defense industry can leverage WAAM (Wire Arc Additive Manufacturing) technology for the production of complex components, optimizing the fabrication of sophisticated structures and reducing manufacturing time.

Oil & Gas

This sector can benefit significantly from the adoption of WAAM (Wire Arc Additive Manufacturing) technology, especially for the production of items with extended lead times, due to its ability to speed up production processes and reduce lead times.

Naval

The use of WAAM (Wire Arc Additive Manufacturing) technology is used to produce metal components, such as structural parts, propellers, and boat parts, reducing production time compared to traditional methods, allowing for greater customization and higher efficiency in repairs and maintenance.

Railway

WAAM (Wire Arc Additive Manufacturing) technology is used to produce and repair complex metal components, such as frames, supports and structural parts, with significant improvement in production time and part customization.

Why Choose ETEO

Choosing ETEO means relying on an experienced and innovative partner in additive manufacturing. With our technology and commitment to excellence, we can turn your ideas into reality, ensuring quality, efficiency and quick turnaround time